“Elevating Steel Connection Precision in Construction”

Let us explore how Building Information Modeling (BIM) is changing the game in steel construction by enhancing the precision of steel connections. We will discuss how BIM seamlessly integrates with digital tools, streamlining the design process and setting a new standard for excellence.

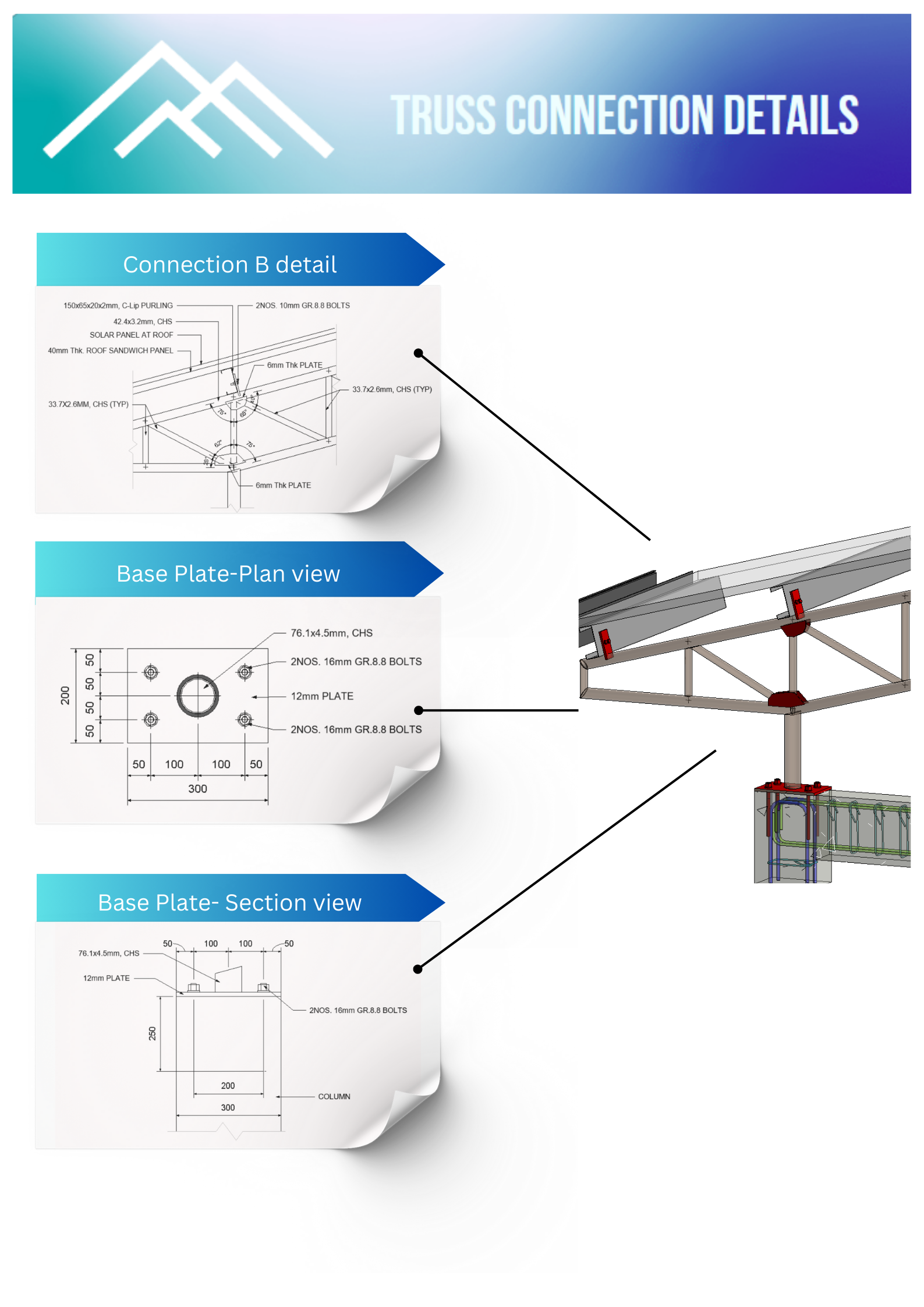

Precision in Steel Connection Design:

BIM’s 3D modeling allows engineers to finely detail steel connections, ensuring they fit perfectly into the larger structural picture. This precision enhances safety, efficiency, and the overall quality of construction projects.

Seamless Integration with Digital Tools:

BIM’s strength lies in its smooth integration with digital tools. This ensures a unified workflow, reducing errors and improving communication across the project team, from design to execution.

Efficiency through Clash Detection:

BIM’s clash detection feature is a game-changer. It spots potential clashes in the design early on, helping engineers make adjustments promptly and ensuring seamless alignment of steel connections.

Parametric Adjustments for Flexibility:

BIM’s parametric capabilities provide flexibility, allowing engineers to adapt steel connections to design changes and site-specific needs. Real-time adjustments optimize structural performance efficiently.

Streamlining Design with Collaboration:

BIM’s collaborative platform fosters real-time communication among stakeholders, speeding up decision-making and preventing issues before construction. This streamlined process minimizes delays and ensures accurate fabrication of steel connections.

Setting a New Standard in Steel Connection Excellence:

In conclusion, BIM is setting a new standard for excellence in steel connection details. Its precision, seamless integration with digital tools, clash detection, parametric adjustments, and collaborative features make it an essential tool for safer, more efficient, and higher-quality steel construction projects.